PVC Sheet Tool Cases

The purpose of developing an PVC sheet tool case is so boys can make a carry-case and storage case for power tools and other items. This can be helpful to the family if boys make custom cases for their father for his tools or for their mother to store things related to home management. When the boys grow to be adults, they can use the same knowledge to create their own custom tool cases and put their own shop or homes in order so everything has its place and is well organized.

The Bosch drill that I purchased in 2012 came with a nice molded plastic carry case as seen in the image above.

The drill also came with a “tool-roll-pouch” (seen in the left side of the case). This pouch holds various sized drill bits and accessories that were included with the purchase of the drill. There is also ample room within the box for other accessories and additional drill bits. This complete set (with molded plastic carry-case) is beneficial in keeping tools organized and is easy to transport and store. However, the more recent power tools I purchased in 2022, no longer came with nice molded carry cases like the drill set I purchased in 2012.

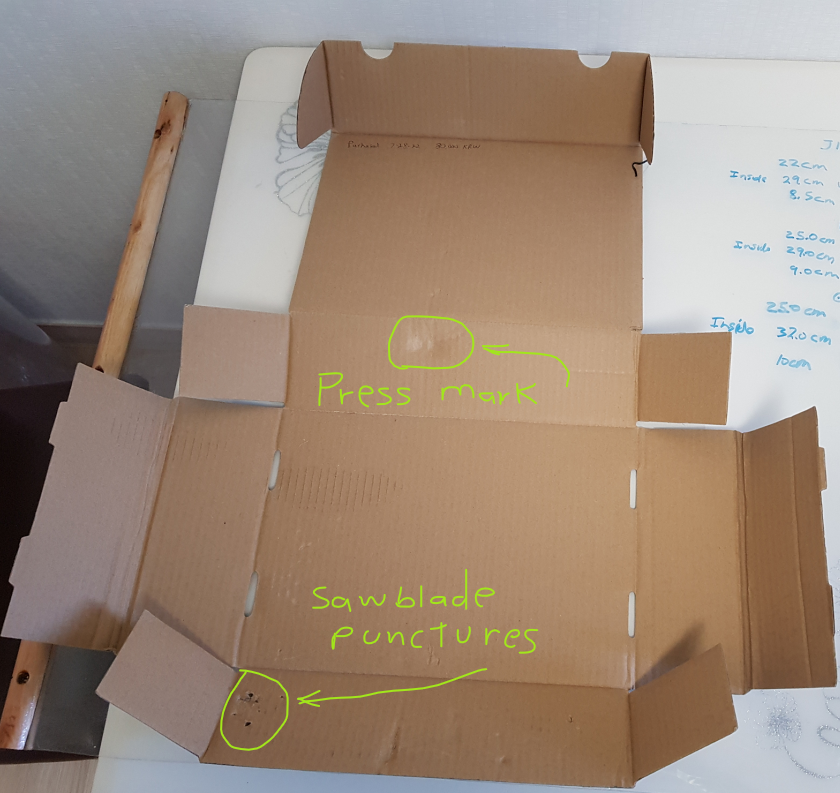

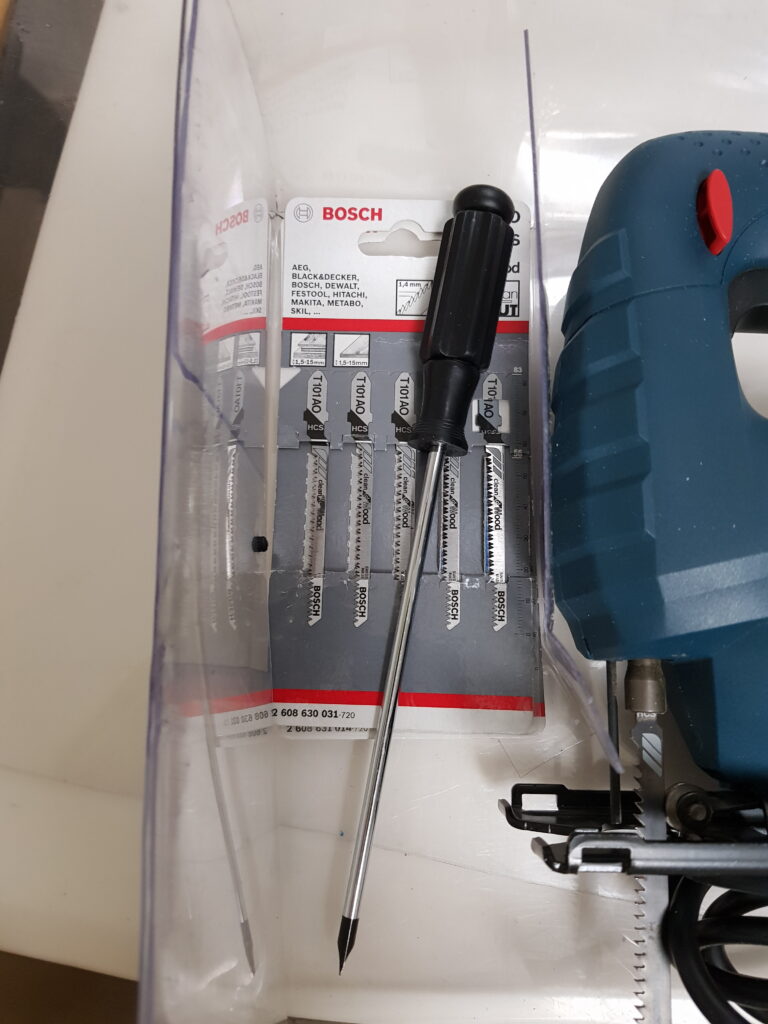

This Bosch jigsaw for example was shipped in a cardboard box as disassembled. When I installed the blade to use it, then the jigsaw no longer fits in the box properly. The blade punctures the cardboard in the front-side of the box while the top of the handle is smashing into the cardboard on the back-side of the box making it difficult to close the box.

I want to keep the blade installed so that I can use it instantly without having to install the blade using the blade change tool. But keeping the blade in the jigsaw was a problem causing the box to be deformed and punctured and keeping it from closing. Therefore, I wanted to create my own custom tool case of larger dimensions and make it out of acrylic sheet which is strong and resists punctures and deformation.

Designing a Tool Case to Fit All My Power Tools

This Bosch Heat Gun also came in a cardboard box without a molded plastic carry-case.

I measured the sizes of the tools and accessories I wanted to store then looked for a common size for making tool cases that would fit each of the power tools I purchased.

The Bosch angle grinder (seen above) also needed to have a bigger case. I recorded the sizes required to store each type of power tools then came up with a “common-size” that would fit each of the power tools I wanted to store.

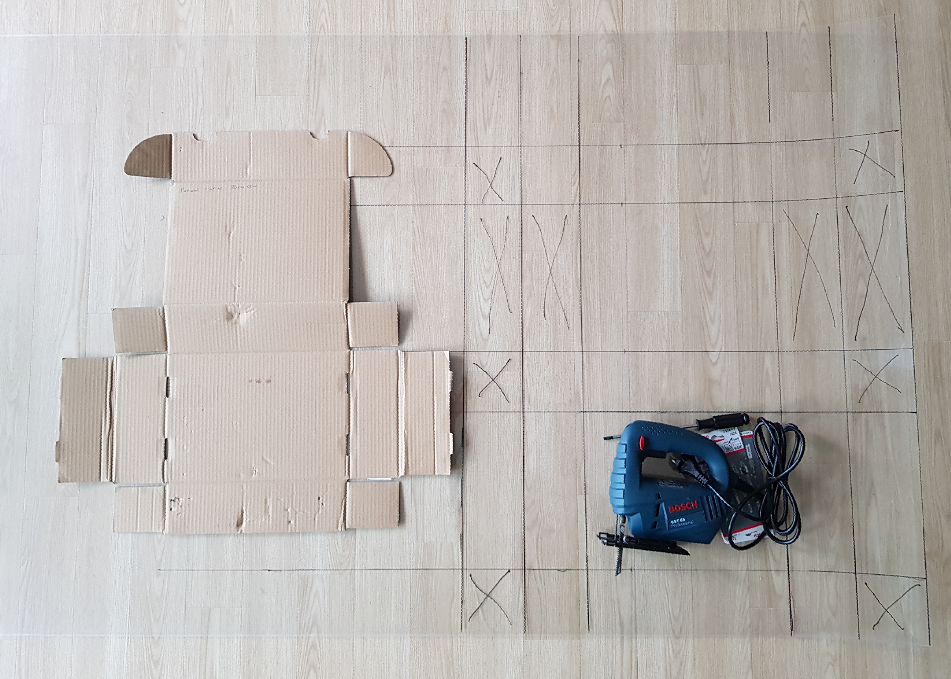

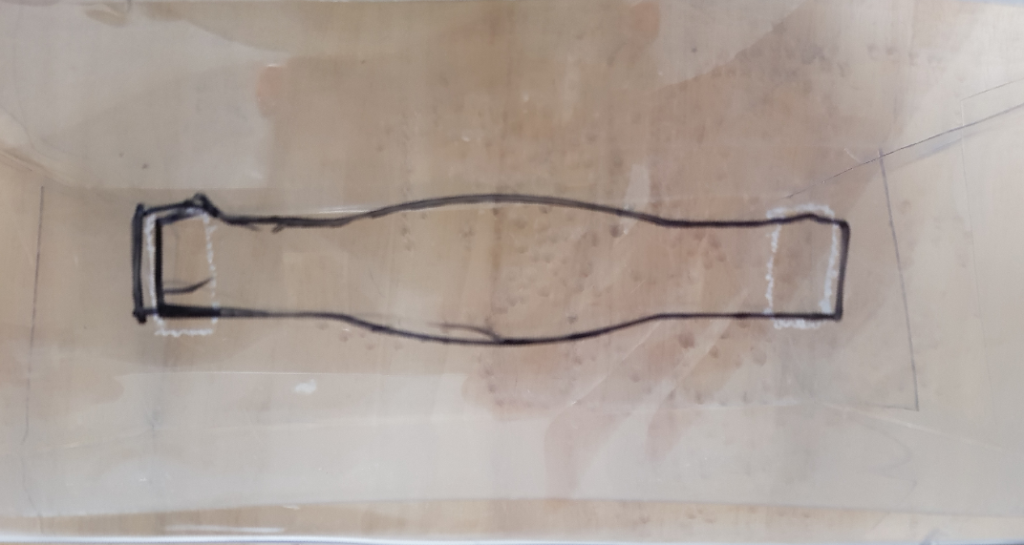

After coming up with the common dimensions, then I used these dimensions on the same pattern of box layout as seen above.

The original cardboard box to the left was laid out on PVC sheet using enlarged custom dimensions. The jigsaw sits in the square that will become the final inside dimension of the box. The parts marked with an “X” are those parts to be cutout and discarded.

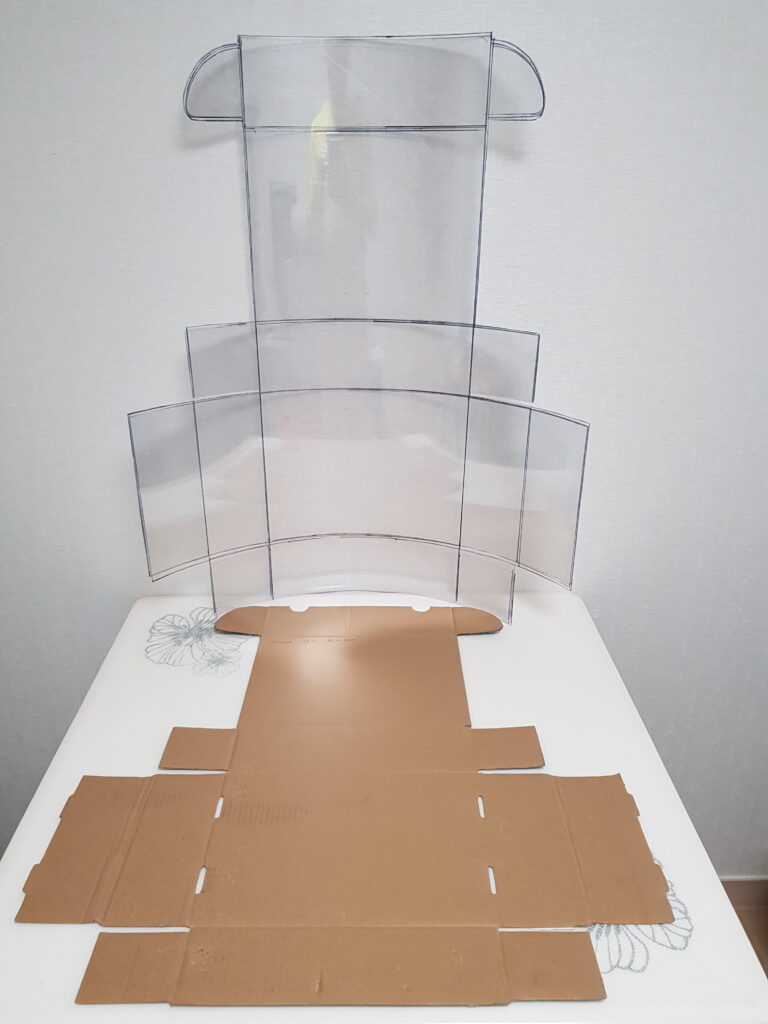

The cardboard box layout was the same pattern I used to create the new PVC sheet tool case (except I used my own enlarged dimensions). Pictured above are three-patterns cutout and ready for folding into tool cases.

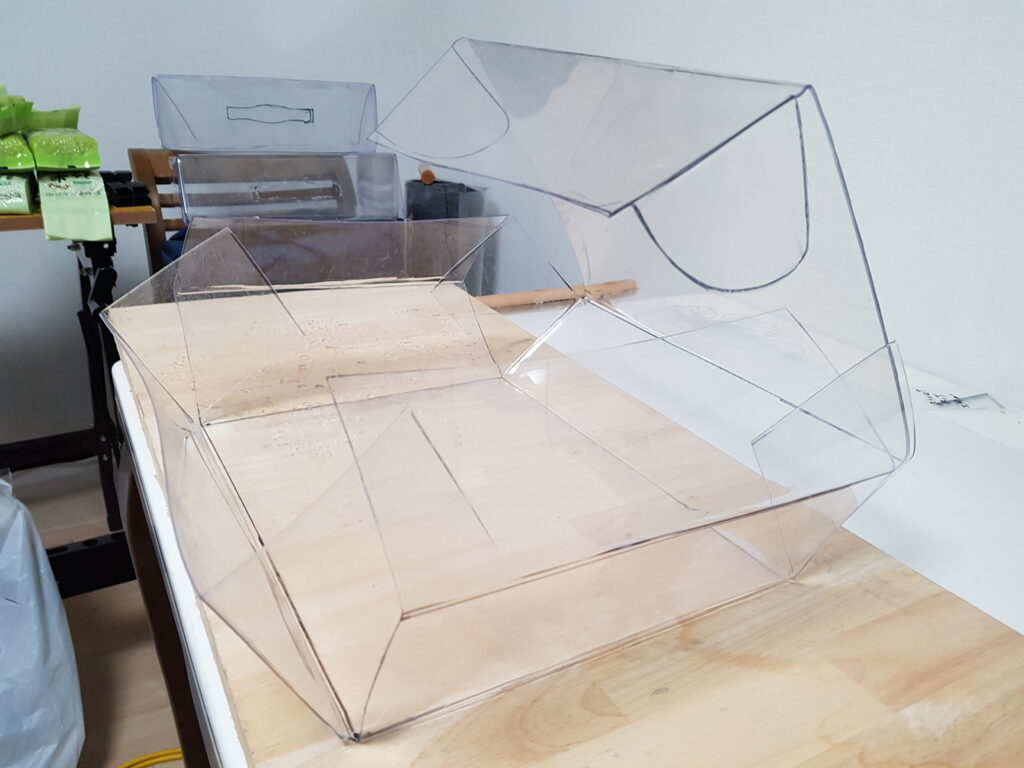

I laid the lines over the edge of a board then heated the PVC sheet with a heat gun until it could be bent into a 90-degree angle (being careful not overheat and melt the PVC sheet).

Bending along the lines causes the formation of a strong PVC sheet tool case of custom dimensions.

After all of the bends are made along the lines then the shape of the box takes form into the final tool case.

Installing Carry Handle

I found a plastic carry handle on a food box and utilized this handle for my tool case.

This handle turned out to be perfect for my tool case without having to fabricate my own out of web-strap or other material. I was able to find the company website information printed on the handle and the company kindly sent me some samples for free (normally they only sell a minimum of 500-pieces per order).

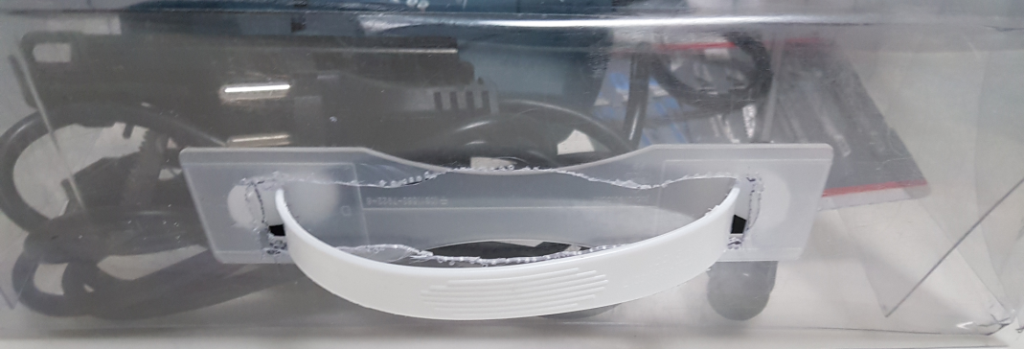

I was able to drill out a slot using a tiny 1mm drill bit then cut along the perforations with a knife to create a slot for the carry handles to fit.

The outside flap also needed a slot so that the handle could pass through the flap and be grasped while being carried. I just traced the handle-hole from the food box onto my PVC sheet tool case.

When the case is closed, then the handle can pass through this slot-cutout in the outer flap so it can be carried. It also has an advantage for storage because the handle lays flat when not in use.

Once the handles are installed then the boxes can be used for tool storage. Other improvements will be brackets and pockets to secure tools inside and for storage of accessories like cutting blades or abrasive disks.

Divider to Secure Jigsaw within the Tool Case

In the image above, I cut some PVC sheet and attached it to the bottom of the case using rivets. This holds the jigsaw in place keeping the weight of the jigsaw centered under the carry handle.

The divider serves a dual-purpose in that it holds the jigsaw (centered under the carry-handle) and the space to the left of the divider also creates a compartment where the spare jigsaw blades and the blade-change tool are kept.

Above the jigsaw is held into place by the divider so that the weight of the jigsaw is centered under the carry-handle. This makes a big difference when the handle is lifted so that the heavy jigsaw can be carried comfortably without having too much weight off-center (which would cause the handle to pull to one side or the other). Now it is perfectly balanced with the weight centered under the carry handle.

The PVC sheet is incredibly tough and I even broke two 1mm drill bits trying to drill out the handle slots and I had to use a great deal of force to push a knife blade through the perforations made by the drill. Cardboard is a temporary material only good for shipping the product but it does not last long for everyday use. This is why the acrylic sheet tool case is much more durable than cardboard!

I created four tool cases to hold my power tools and made them all the same size which is big enough to fit all of them.

The first case I made was rather rough in quality and the succeeding boxes seems to be better as I gained experience in folding tough PVC sheet with a heat gun. This should be normal that boys will also become better at various tasks as they gain experience. It is never a waste for them to make mistakes or do rough work on their first projects because this is how they learn and improve.

Again, the purpose of making these tool case projects is to give boys experience in making useful things that can help their parents at home. It will also help the boys to grow up to become self-sufficient and create their own tool cases and tools and other things that they might need as adults at home or when working a trade or business.

Tool Case for Angle Grinder and Accessories

The original Bosch shipping carton was made of cardboard and it held the grinder in a dissembled condition. I wanted to have the cutting disk installed on the machine and ready to use so I would not have to spend time assembling the grinder every time that I needed to cut something.

I used some left-over PVC sheet “scrap” material to create a pocket for holding the various grinding disks and sanding disks. I also created a space for placing the “disk-change wrench” (which is needed every time that a different type of disk is changed on the machine.) The disk-change wrench and the different types of abrasive disks must stay with the machine for this reason. I used rivets to hold the acrylic sheet material together which formed the pockets that I needed for the accessories.

The machine also comes with some extra “carbon brushes” to be changed on the motor periodically. I kept these with the machine so they would not be lost and placed them into a small plastic bottle and labeled them. This bottle happened to fit well into the same pocket created to hold the disk-change-wrench.

I did not create a pocket or folder to hold the operator’s manual. Instead, this manual was placed into a separate file (in my office desk) because it is seldom used and generally will not last long if kept within the tool case.

The tool case I made is rather “rough” in appearance but it is for “personal use only” so function was more important than beauty. However, if a boy wanted to make tool cases for sale, then he would have to attain to a high degree of quality in order to make these on a professional level to sell them. Again, it depends upon the end-use and if the boys are making them for their own personal use, then function is more important than beauty.

Heat Gun Tool Case

The heat gun is used to heat and bend PVC pipes and works well for shaping PVC sheets and other materials. I created a small divider box to hold the heat gun accessories and riveted the edges to the inside of the tool case. Again, this is rough work only for my own personal use but it is fully functional.

Originally, I was going to make one big toolbox for all of the tools but I abandoned that idea because it would have been too big and heavy. These individual tool cases work nice because I can grab whatever power tool I need at the time and all of the accessories are together with the power tool.

This tool case contains the hot glue gun and a rivet gun with partitions for rivets and a side divider for storing glue-sticks for the hot-glue gun. Again, this is really rough in appearance and is suited for function and not beauty.

These cases were roughly about 10 cm thick so the final dimensions fit well with all four cases on the same shelf. Our boys can learn how to consider all of the factors when they make their designs (such as tool cases). They have to consider the size of the items they want to store as well as the available storage space. If I made one big tool case for all of the tools then it would not have fit on this shelf and it would have been too heavy to carry. Having individual tool cases allows me to select just the tools I need instead of carrying everything with me. It is much better to organize when each tool has its own case together with the related accessories which go together with each power tool.