Grinder and Step Drill and Vise

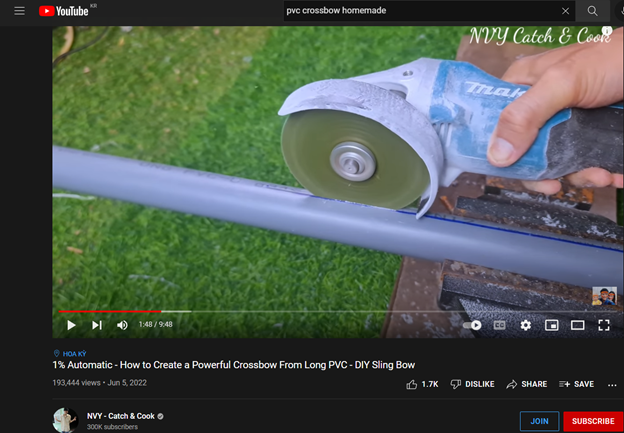

Above is a small angle-grinder which is useful for boy projects and can cut metal and plastic and just about any type of material. It comes with various types of disk cutter blades and can be used for cutting and sanding and shaping of most materials.

There are many different types of cutting and abrasive disks that can be purchased with an angle grinder to work with many types of materials.

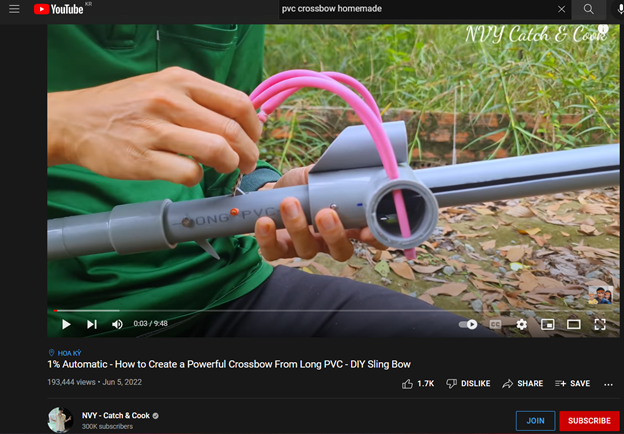

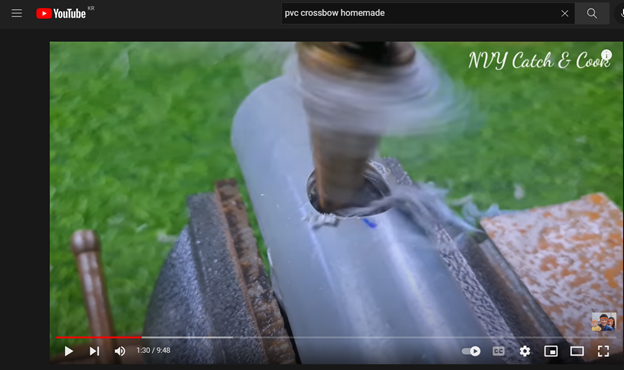

The above image (linked to Utube) shows the creation of a crossbow made from PVC pipes. This is an good example how how certain tools are necessary for specific purposes.

Need for Angle Grinder

Above, an angle grinder is used to cut a long slot in the PVC pipe. If a boy tried to use a drill to open one end and then tried to use a jig saw then it would be difficult because the blade of the jig saw would strike the interior of the PVC pipe. This is an example of how an angle grinder is the best tool for the job because it can cut a long and straight slot without touching the inside of the opposite wall of the PVC pipe.

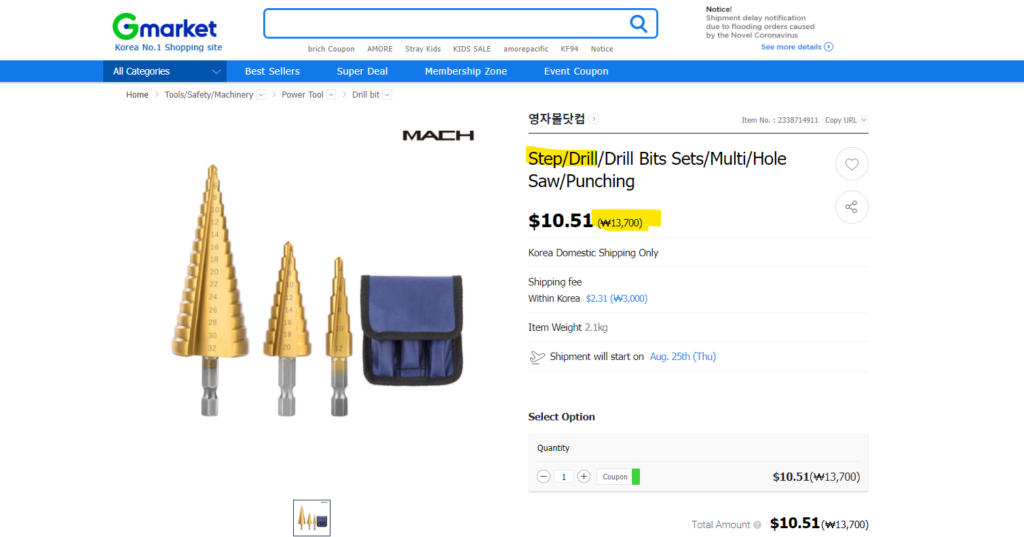

Need for Step Drill Bit

Step drill bits are very useful for cutting large diameter holes up to 3.2 cm in diameter.

This set can drill holes from 4mm to 32mm in diameter. The best part is that they used a 1/4″ shank so they can fit any ordinary 1/4″ drill chuck. It would be difficult to find a “twist” drill bit that could drill a 3.2cm diameter hole. If such a drill bit was made it would be hugely expensive and require a huge drill chuck and special drilling machine to hold it. But with a step-drill bit and ordinary 1/4″ chuck can be used to drill up to a 3.2cm diameter hole.

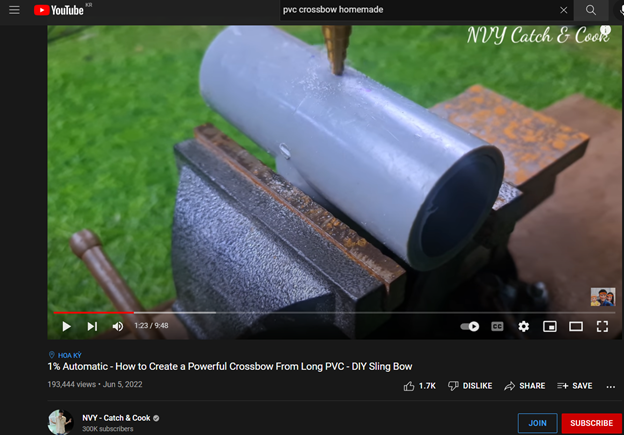

The PVC Crossbow project above needs to make a large diameter hold as big as the PVC pipe used for this job.

A step-drill bit will widen the hole to a larger diameter with each “step” that is drilled into the material with the hole becoming progressively larger at every step.

As the step-drill-bit drills down deeper then the hole becomes progressively larger in diameter (up to 32mm).

The one doing the drilling only has to stop on the step that matches the diameter of the hole he needs to drill.

This is a larger diameter hole that what is available for most sizes of “twist” type drill bits.

This finished hole diameter is large enough to accept the full diameter of the mating PVC pipe to be inserted into it.

This is about the only proper way of drilling a hole up to 32mm in diameter which is the most cost effective and can use any ordinary 1/4″ drill chuck and drill to power it.

This is an example of how some tools are necessary to preform a job like drilling a large diameter hole up to 32mm in diameter. This is also handy because any hole size from 4mm to 32mm can be drilled by one drill bit. Thus a boy can own only one of these step-drill bits and make any size hole he needs between 4mm to 32mm in diameter.

Portable Workbench and Vise

A portable work bench and a vise to hold materials is an essential tool for any boys doing their own projects.

It is possible to hold materials by hand without a workbench or a vise as seen in the image above. But it should be noted however that there are dangers and risks involved with this practice. When using power tools a cutting blade could jump suddenly and cut the hand holding the project. If the worker is kneeling beside the material and the cutting blade suddenly jumps it could injure a man’s leg or organs in disastrous effect. This is why it is important for a boy to have a work bench and a vise to securely hold the materials he is working on. This is for his own safety and he can do a better job when he has a proper means to secure his materials while working with power tools.

See the link “Portable Workbench” for more details.